-

瀚峰彩色印刷事業有限公司印刷專員黃先生手機 0910-243496 Line : 0910243496 我加了才能看到妳的資訊漢斯首頁FTP檔案上傳 帳號 : hans@hans-p-d.com.tw 密碼 : 29982

瀚峰彩色印刷事業有限公司印刷專員黃先生手機 0910-243496 Line : 0910243496 我加了才能看到妳的資訊漢斯首頁FTP檔案上傳 帳號 : hans@hans-p-d.com.tw 密碼 : 29982242台灣新北市新莊區化成路63巷6號之4樓之3

電話 : 02 29982117 電話 : 02 229982118 分機 566 業務專員許小姐

傳真 : 02 2998-6588 Line ID : @hans.co 公司 line://ti/p/@hans.co

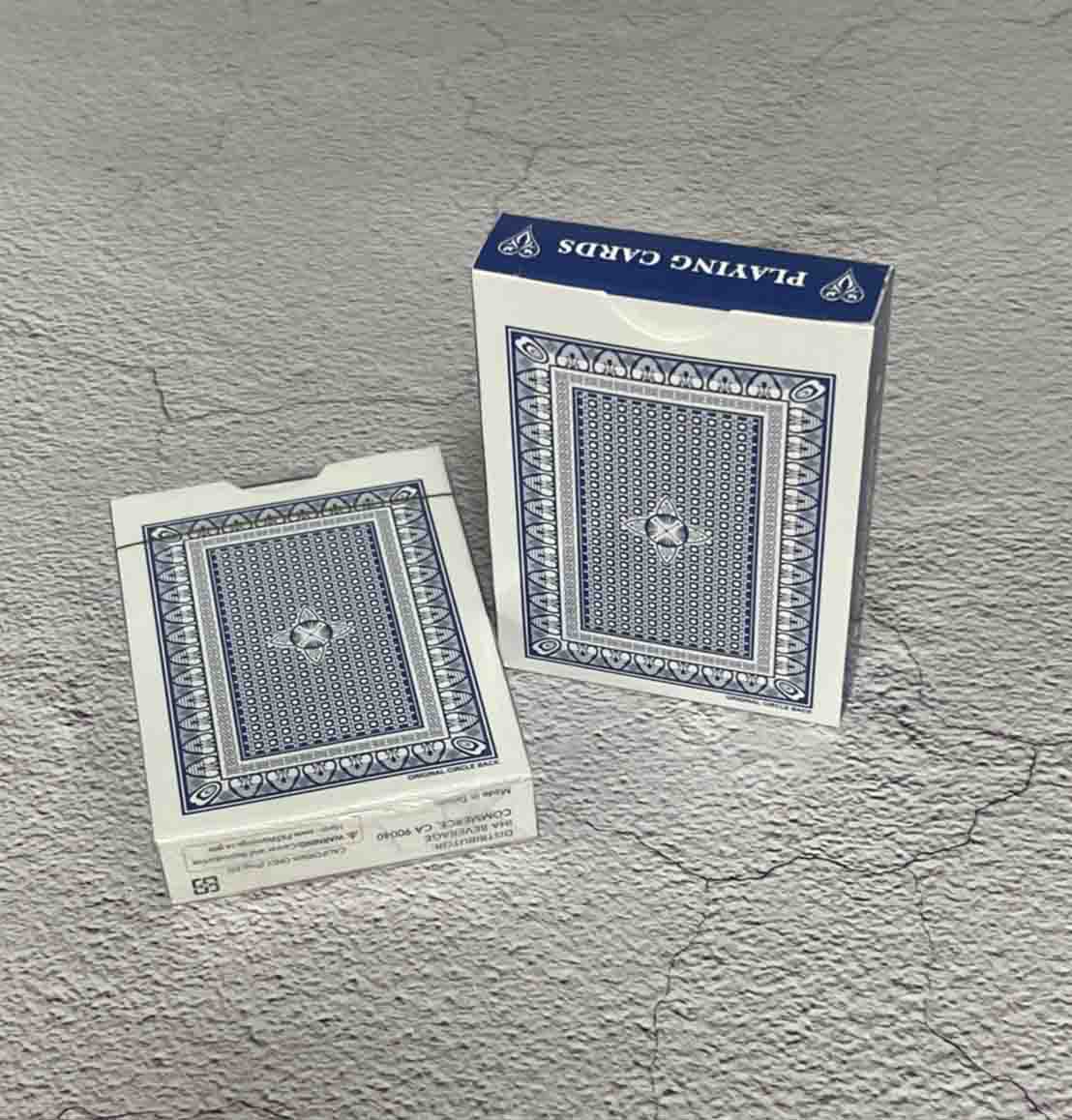

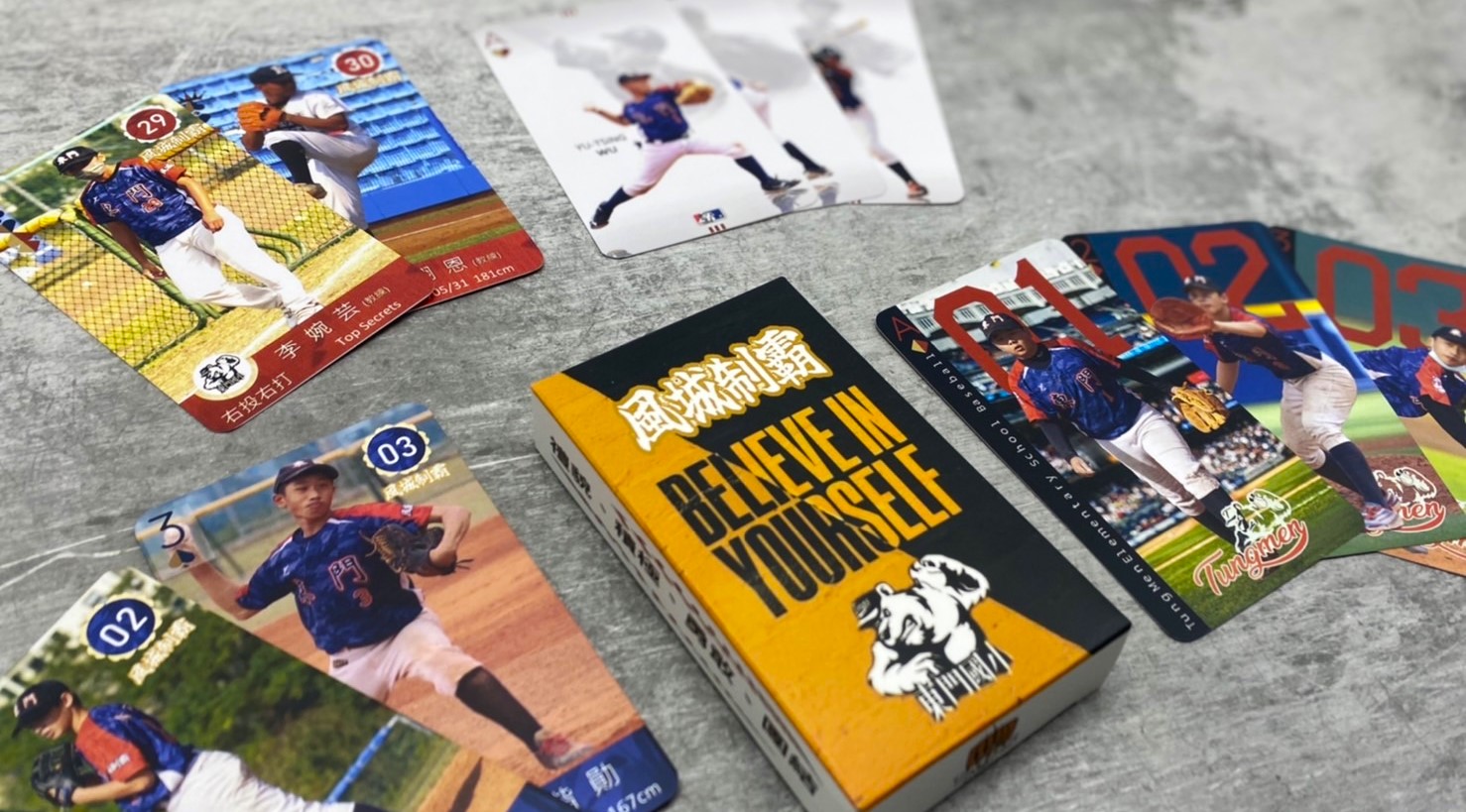

Fanfon International Printing Co., Ltd.4F-3, No. 6, Lane 63, Huacheng Road, Xinzhuang District, New Taipei City 242, Taiwan (R.O.C.)Phone: +886 2 29982117 +886 2 29982118 Special 566 Miss Xu Fax: +886 2 2998-6588Home FTP File Upload File Account : hans@hans-p-d.com.tw Password : 29982Whats App https://wa.me/message/RAC72UECWFY4P1我們秉持著誠信服務客戶,協助客戶印刷的品質要求,讓每一件印刷品都是藝術品,從品質,顏色,材質,裝訂,打樣種種,瀚峰提供給客戶最好的印刷品質,客戶的滿意一直是我們的堅持 ...更增進了彼此友誼。We uphold the integrity of serving customers and assist customers in printing quality requirements, so that every print is a work of art. From quality, color, material, binding, proofing, Hanfeng provides customers with the best printing quality and customer satisfaction. It has always been our persistence...and it has enhanced mutual friendship.撲克牌印刷廠,撲克牌印刷公司,撲克牌印刷網站,臺北市撲克牌印刷廠,新北市撲克牌印刷廠,新竹撲克牌印刷廠,新竹縣撲克牌印刷廠,中壢撲克牌印刷廠,桃園撲克牌印刷廠,台中撲克牌印刷廠,彰化撲克牌印刷廠,高雄撲克牌印刷廠,台南撲克牌印刷廠,嘉義撲克牌印刷廠,屏東撲克牌印刷廠,台東撲克牌印刷廠,花蓮撲克牌印刷工廠,南投撲克牌印刷工廠,雲林撲克牌印刷工廠,員林撲克牌印刷工桌遊製作成品尺寸:58x88mm(製作尺寸:61x93.5mm)(標準撲克牌) [按此連結--> 撲克牌製作說明及注意事項]內容:全彩雙面印刷、撲克牌銅版紙專用材質(厚約300磅,含兩面水性上光、圓角)牌數:數字牌面52張+ 鬼牌2張+ 廣告牌1張= 55張

Playing card printing (handmade box / game card / board game printing)Playing cards, board game puzzle games, board game card boxes, board game card sets, board game cards,, board game card boxes, bridge towers, tarot cards, magic cards, bridge cards, plastic game cards, posters, monopoly Games, hard boxes, book boxes, hardcover boxes, wet pasting boxes, handmade boxes, card making, brocade boxes, 3D card printing, 3C paper cards, table standing cards, hard box gift boxes are customized according to customers.Playing cards that are loved by children to adults, not only have a lot of ways to play, but also can be used for divination, magic, etc., big second, bridge, piggy, stud, red dot, Texas hold'em, baccarat, two 11 o'clock, shooting the dragon goal, platooning seven (Solitaire), heart disease, and friends playing games together? Playing cards can not only be used to play games, there are a wide variety of cards with various patterns, but the collection is also very pleasing to the eye, and it can also add a bit of fun to life!Understanding the content of playing card printing and production (hand-made boxes, ditch boxes, thick elevators)●Dimensions: Length X Width X Height cm.●Paper types: single copper T, gray copper card, diamond card paper, watery white card paper, cupronickel card paper, copper xi card paper, gold and silver foil paper, transparent PET/PVC, kraft paper art paper (imported paper)●Paper thickness: paper thickness (250 pounds, 300 pounds, 400 pounds, 500 pounds, 600 pounds) 0.1 cm maximum●Printing color: color printing, single color printing, two-color printing + special color (laser printing or UV printing).●Carton glazing: water-based light, upper light, fog light, flannel, frosted, matte or partial light, UV glazing (UV is divided into bright UV, fog UV, and release UV).●Printing quantity: several color boxes●Types of knife molds: general knife molds, Japanese knife molds, Swiss knife molds, steel knife molds, grooving, laser knife molds, hardware knife molds, etc... (most of them have machine cutting)●Proofing method: digital sample or formal sample (printing or proofing directly on the machine).●Processing methods: there are shapes, threading, iron wire, bronzing silver, embossing, copper buckle, etc...Playing card printing time process productionQuotation and transaction signing ==> design (product photography) ==> finished draft editing ==> proofreading ==> digital sample (formal sample) 1 day ==> 3 days for printing paper ==> 2 days for mounting corrugated paper = => 1 day for printing==> 3 days for printing ==> 2 days for glazing ==> 2 days for die-opening ==> 1 day for working ==> 5 days for manual box ==> Packaging and shipping (The whole process is about 20 days) Excluding design, photography and construction撲克牌印刷 ( 手工盒 / 遊戲卡/ 桌遊印刷 )撲克牌、桌遊益智遊戲、桌遊卡盒、桌遊卡套、桌遊卡片、 、桌遊卡盒裝、橋牌塔、塔羅牌、魔術牌、橋牌、塑膠遊戲卡、海報、大富翁遊戲、硬盒、書型盒、精裝盒、濕糊盒、手工盒、紙牌製作、錦盒、3D卡印刷、3C紙卡、桌上立牌、硬盒禮盒依客戶客製化。從小孩到大人都很喜愛的撲克牌,不但有非常多玩法,還能用來占卜、變魔術等、大老二、橋牌、拱豬、梭哈、檢紅點、德州撲克、百家樂、二十一點、射龍門、排七(接龍)、心臟病、朋友們一起玩遊戲的喜悅呢?撲克牌不只可以拿來玩遊戲,種類繁多又花樣多變的牌,只是收集起來也很賞心悅目,還可以為生活增添幾分趣味呢!撲克牌印刷製作內容了解 ( 手工盒、刨溝盒、厚吊卡 )●尺寸開數 :長 X 寬 X 高公分.●紙張種類 :單銅T、灰銅卡、鑽卡紙、水樣白卡紙、白銅卡紙、銅西卡紙、金銀箔紙張,透明PET/ PVC,牛皮紙美術紙類(進口紙)●對裱厚度 :紙張厚度(250磅、300磅、400磅、500磅、600磅) 0.1公分最高●印刷顏色 :彩色印刷、單色印刷、雙色印刷 +特別色 ( 雷射印刷或UV印刷 ).●紙盒上光 :水性光、上亮光、上霧光、絨布、磨砂、消光或加局部光、UV上光(UV又分為亮UV、霧UV、離型UV)。●印刷數量 :幾個彩盒、( 有關於如何拼模比較合適 )●刀模種類 :一般刀模、日本刀模、瑞士刀模、鋼刀模、刨溝、鐳射刀模、五金刀模等... ( 大部分有機器割 )●打樣方式 :數位樣或是正式樣 ( 直接上機印刷打樣或打樣 ).●加工方式 :有形狀、穿線、鐵絲、燙金銀、打凸、打銅扣等………撲克牌印刷時間流程製作報價成交簽約 ==>設計(產品攝影)==>完稿編輯==>校稿==>打數位樣(打正式樣) 1天==>印刷紙張3天==>裱瓦楞紙張2天==>曬版1天==>印刷3天==>上光2天==>開刀模2天==>扎工1天==>手工盒5天==>包裝出貨( 整個流程大約20天 ) 不含設計攝影趕建另計Manual gluingGame card, poker card, board game puzzle game, board game card box, board game card set, board game card, board game card box, bridge tower, tarot card, magic card, bridge card, plastic game card, poster , Monopoly Game, Hard Box, Book Box, Hardcover Box, Wet Paste Box, Handmade Box, Card Making, Brocade Box, 3D Card Printing, 3C Paper Card, Table Standing Card, Hard Box Gift Box, customized according to customersUnderstanding of the content of manual paste box printing production (hand box, ditch box, thick elevator)●Dimensions: Length X Width X Height cm.●Paper types: single copper T, gray copper card, diamond card paper, watery white card paper, cupronickel card paper, copper xi card paper, gold and silver foil paper, transparent PET/PVC, kraft paper art paper (imported paper)●On-mount paper: gray cardboard, a few ounces of 24 x 33 size, 8 ounces-10 ounces-12 ounces-14 ounces-16 ounces-18 ounces-32 ounces, ounces can be ordered 13,000 yuan per ton, 18 ounces●Paper thickness: paper thickness (600 lb, 800 lb, 1000 lb, 1200 lb, 1400 lb, 2000 lb) 0.1 to 0.3 cm maximum●Printing color: color printing, single color printing, two-color printing + special color (laser printing or UV printing).●Carton glazing: water-based light, upper light, fog light, flannel, frosted, matte or partial light, UV glazing (UV is divided into bright UV, fog UV, and release UV).●Printing quantity: several color boxes●Types of knife molds: general knife molds, Japanese knife molds, Swiss knife molds, steel knife molds, grooving, laser knife molds, hardware knife molds, etc... (most of them have machine cutting)●Proofing method: digital sample or formal sample (printing or proofing directly on the machine).●Processing methods: there are shapes, threading, iron wire, bronzing silver, embossing, copper buckle, etc...Manual glue box printing time process productionQuotation and transaction signing ==> design (product photography) ==> finished draft editing ==> proofreading ==> digital sample (formal sample) 1 day ==> 3 days for printing paper ==> 2 days for mounting corrugated paper = => 1 day for printing==> 3 days for printing ==> 2 days for glazing ==> 2 days for die-opening ==> 1 day for working ==> 5 days for manual box ==> Packaging and shipping (The whole process is about 20 days) Excluding design, photography and constructionWet paste boxExquisite packaging gift box, wet paste box, handmade paper box, hard paper box, book box, hardcover box, scripture, Buddhist book, mobile phone box, gift box, book box, wine box, heaven and earth box, playing card box, board game benefit Smart games, board game card boxes, board game card sets, board game cards, board game card boxes, bridge towers, tarot cards, magic cards, bridge cards, brocade boxes, 3D card printing, 3C paper cards, table standing cards , Hard box customized according to customersUnderstanding the content of wet paste box printing production (hand box, gouging box, thick elevator)●Dimensions: Length X Width X Height cm.●Paper types: single copper T, gray copper card, diamond card paper, watery white card paper, cupronickel card paper, copper xi card paper, gold and silver foil paper, transparent PET/PVC, kraft paper art paper (imported paper)●On-mount paper: Gray cardboard, a few ounces, 24 x 33 size, 8 ounces-10 ounces-12 ounces-14 ounces-16 ounces-18 ounces-single white 32 ounces, ounces can be ordered, 13,000 yuan per ton, 18 ounces●Paper thickness: paper thickness (600 lb, 800 lb, 1000 lb, 1200 lb, 1400 lb, 2000 lb) 0.1 to 0.3 cm maximum●Printing color: color printing, single color printing, two-color printing + special color (laser printing or UV printing).●Carton glazing: water-based light, upper light, fog light, flannel, frosted, matte or partial light, UV glazing (UV is divided into bright UV, fog UV, and release UV).●Printing quantity: several color boxes●Types of knife molds: general knife molds, Japanese knife molds, Swiss knife molds, steel knife molds, grooving, laser knife molds, hardware knife molds, etc... (most of them have machine cutting)●Proofing method: digital sample or formal sample (printing or proofing directly on the machine).●Processing methods: there are shapes, threading, iron wire, bronzing silver, embossing, copper buckle, etc...Wet paste box printing time process productionQuotation and transaction signing ==> design (product photography) ==> final draft editing ==> proofreading ==> digital proofing (formal proof proofing) 1 day ==> 3 days for printing paper ==> 2 days for mounting thick paper ==>1 day for printing==>3 days for printing==>2 days for glazing==>2 days for die-cutting ==>1 day for workmanship ==>10 days for manual box ==>Packing and shipping (the whole process Approximately 30 days) Excluding design, photography and construction

Playing card printing (handmade box / game card / board game printing)Playing cards, board game puzzle games, board game card boxes, board game card sets, board game cards,, board game card boxes, bridge towers, tarot cards, magic cards, bridge cards, plastic game cards, posters, monopoly Games, hard boxes, book boxes, hardcover boxes, wet pasting boxes, handmade boxes, card making, brocade boxes, 3D card printing, 3C paper cards, table standing cards, hard box gift boxes are customized according to customers.Playing cards that are loved by children to adults, not only have a lot of ways to play, but also can be used for divination, magic, etc., big second, bridge, piggy, stud, red dot, Texas hold'em, baccarat, two 11 o'clock, shooting the dragon goal, platooning seven (Solitaire), heart disease, and friends playing games together? Playing cards can not only be used to play games, there are a wide variety of cards with various patterns, but the collection is also very pleasing to the eye, and it can also add a bit of fun to life!Understanding the content of playing card printing and production (hand-made boxes, ditch boxes, thick elevators)●Dimensions: Length X Width X Height cm.●Paper types: single copper T, gray copper card, diamond card paper, watery white card paper, cupronickel card paper, copper xi card paper, gold and silver foil paper, transparent PET/PVC, kraft paper art paper (imported paper)●Paper thickness: paper thickness (250 pounds, 300 pounds, 400 pounds, 500 pounds, 600 pounds) 0.1 cm maximum●Printing color: color printing, single color printing, two-color printing + special color (laser printing or UV printing).●Carton glazing: water-based light, upper light, fog light, flannel, frosted, matte or partial light, UV glazing (UV is divided into bright UV, fog UV, and release UV).●Printing quantity: several color boxes●Types of knife molds: general knife molds, Japanese knife molds, Swiss knife molds, steel knife molds, grooving, laser knife molds, hardware knife molds, etc... (most of them have machine cutting)●Proofing method: digital sample or formal sample (printing or proofing directly on the machine).●Processing methods: there are shapes, threading, iron wire, bronzing silver, embossing, copper buckle, etc...Playing card printing time process productionQuotation and transaction signing ==> design (product photography) ==> finished draft editing ==> proofreading ==> digital sample (formal sample) 1 day ==> 3 days for printing paper ==> 2 days for mounting corrugated paper = => 1 day for printing==> 3 days for printing ==> 2 days for glazing ==> 2 days for die-opening ==> 1 day for working ==> 5 days for manual box ==> Packaging and shipping (The whole process is about 20 days) Excluding design, photography and construction撲克牌印刷 ( 手工盒 / 遊戲卡/ 桌遊印刷 )撲克牌、桌遊益智遊戲、桌遊卡盒、桌遊卡套、桌遊卡片、 、桌遊卡盒裝、橋牌塔、塔羅牌、魔術牌、橋牌、塑膠遊戲卡、海報、大富翁遊戲、硬盒、書型盒、精裝盒、濕糊盒、手工盒、紙牌製作、錦盒、3D卡印刷、3C紙卡、桌上立牌、硬盒禮盒依客戶客製化。從小孩到大人都很喜愛的撲克牌,不但有非常多玩法,還能用來占卜、變魔術等、大老二、橋牌、拱豬、梭哈、檢紅點、德州撲克、百家樂、二十一點、射龍門、排七(接龍)、心臟病、朋友們一起玩遊戲的喜悅呢?撲克牌不只可以拿來玩遊戲,種類繁多又花樣多變的牌,只是收集起來也很賞心悅目,還可以為生活增添幾分趣味呢!撲克牌印刷製作內容了解 ( 手工盒、刨溝盒、厚吊卡 )●尺寸開數 :長 X 寬 X 高公分.●紙張種類 :單銅T、灰銅卡、鑽卡紙、水樣白卡紙、白銅卡紙、銅西卡紙、金銀箔紙張,透明PET/ PVC,牛皮紙美術紙類(進口紙)●對裱厚度 :紙張厚度(250磅、300磅、400磅、500磅、600磅) 0.1公分最高●印刷顏色 :彩色印刷、單色印刷、雙色印刷 +特別色 ( 雷射印刷或UV印刷 ).●紙盒上光 :水性光、上亮光、上霧光、絨布、磨砂、消光或加局部光、UV上光(UV又分為亮UV、霧UV、離型UV)。●印刷數量 :幾個彩盒、( 有關於如何拼模比較合適 )●刀模種類 :一般刀模、日本刀模、瑞士刀模、鋼刀模、刨溝、鐳射刀模、五金刀模等... ( 大部分有機器割 )●打樣方式 :數位樣或是正式樣 ( 直接上機印刷打樣或打樣 ).●加工方式 :有形狀、穿線、鐵絲、燙金銀、打凸、打銅扣等………撲克牌印刷時間流程製作報價成交簽約 ==>設計(產品攝影)==>完稿編輯==>校稿==>打數位樣(打正式樣) 1天==>印刷紙張3天==>裱瓦楞紙張2天==>曬版1天==>印刷3天==>上光2天==>開刀模2天==>扎工1天==>手工盒5天==>包裝出貨( 整個流程大約20天 ) 不含設計攝影趕建另計Manual gluingGame card, poker card, board game puzzle game, board game card box, board game card set, board game card, board game card box, bridge tower, tarot card, magic card, bridge card, plastic game card, poster , Monopoly Game, Hard Box, Book Box, Hardcover Box, Wet Paste Box, Handmade Box, Card Making, Brocade Box, 3D Card Printing, 3C Paper Card, Table Standing Card, Hard Box Gift Box, customized according to customersUnderstanding of the content of manual paste box printing production (hand box, ditch box, thick elevator)●Dimensions: Length X Width X Height cm.●Paper types: single copper T, gray copper card, diamond card paper, watery white card paper, cupronickel card paper, copper xi card paper, gold and silver foil paper, transparent PET/PVC, kraft paper art paper (imported paper)●On-mount paper: gray cardboard, a few ounces of 24 x 33 size, 8 ounces-10 ounces-12 ounces-14 ounces-16 ounces-18 ounces-32 ounces, ounces can be ordered 13,000 yuan per ton, 18 ounces●Paper thickness: paper thickness (600 lb, 800 lb, 1000 lb, 1200 lb, 1400 lb, 2000 lb) 0.1 to 0.3 cm maximum●Printing color: color printing, single color printing, two-color printing + special color (laser printing or UV printing).●Carton glazing: water-based light, upper light, fog light, flannel, frosted, matte or partial light, UV glazing (UV is divided into bright UV, fog UV, and release UV).●Printing quantity: several color boxes●Types of knife molds: general knife molds, Japanese knife molds, Swiss knife molds, steel knife molds, grooving, laser knife molds, hardware knife molds, etc... (most of them have machine cutting)●Proofing method: digital sample or formal sample (printing or proofing directly on the machine).●Processing methods: there are shapes, threading, iron wire, bronzing silver, embossing, copper buckle, etc...Manual glue box printing time process productionQuotation and transaction signing ==> design (product photography) ==> finished draft editing ==> proofreading ==> digital sample (formal sample) 1 day ==> 3 days for printing paper ==> 2 days for mounting corrugated paper = => 1 day for printing==> 3 days for printing ==> 2 days for glazing ==> 2 days for die-opening ==> 1 day for working ==> 5 days for manual box ==> Packaging and shipping (The whole process is about 20 days) Excluding design, photography and constructionWet paste boxExquisite packaging gift box, wet paste box, handmade paper box, hard paper box, book box, hardcover box, scripture, Buddhist book, mobile phone box, gift box, book box, wine box, heaven and earth box, playing card box, board game benefit Smart games, board game card boxes, board game card sets, board game cards, board game card boxes, bridge towers, tarot cards, magic cards, bridge cards, brocade boxes, 3D card printing, 3C paper cards, table standing cards , Hard box customized according to customersUnderstanding the content of wet paste box printing production (hand box, gouging box, thick elevator)●Dimensions: Length X Width X Height cm.●Paper types: single copper T, gray copper card, diamond card paper, watery white card paper, cupronickel card paper, copper xi card paper, gold and silver foil paper, transparent PET/PVC, kraft paper art paper (imported paper)●On-mount paper: Gray cardboard, a few ounces, 24 x 33 size, 8 ounces-10 ounces-12 ounces-14 ounces-16 ounces-18 ounces-single white 32 ounces, ounces can be ordered, 13,000 yuan per ton, 18 ounces●Paper thickness: paper thickness (600 lb, 800 lb, 1000 lb, 1200 lb, 1400 lb, 2000 lb) 0.1 to 0.3 cm maximum●Printing color: color printing, single color printing, two-color printing + special color (laser printing or UV printing).●Carton glazing: water-based light, upper light, fog light, flannel, frosted, matte or partial light, UV glazing (UV is divided into bright UV, fog UV, and release UV).●Printing quantity: several color boxes●Types of knife molds: general knife molds, Japanese knife molds, Swiss knife molds, steel knife molds, grooving, laser knife molds, hardware knife molds, etc... (most of them have machine cutting)●Proofing method: digital sample or formal sample (printing or proofing directly on the machine).●Processing methods: there are shapes, threading, iron wire, bronzing silver, embossing, copper buckle, etc...Wet paste box printing time process productionQuotation and transaction signing ==> design (product photography) ==> final draft editing ==> proofreading ==> digital proofing (formal proof proofing) 1 day ==> 3 days for printing paper ==> 2 days for mounting thick paper ==>1 day for printing==>3 days for printing==>2 days for glazing==>2 days for die-cutting ==>1 day for workmanship ==>10 days for manual box ==>Packing and shipping (the whole process Approximately 30 days) Excluding design, photography and construction